HENAN FAIR MACHINERY CO.,LTD

1. Henan Fair Machinery & Equipment co., LTD. Is located in China's

national center of zhengzhou city.

2. We Fair Machinery is a research and development,

manufacture, sales, service as one of the large-scale integrated

complete crushing and mixing packaging production line is given

priority to, both well-known enterprise specialized in machinery

and equipment manufacturing since 1997

3. We Fier Machienry has passed the 9001:9001 quality certification

system, the influence in the industry leading, Fier Machienry was

named the national high-tech enterprises.

4. Industry's leading independent research and development center,

supporting research of various kinds of products of equipment needed for production line.

5. We are Specializing in the production of High efficiency, energy saving crushing and mixing and packaging production line, including jaw crusher, impact crusher,hammer crusher, Wood Crusher,Metal crusher machine, putty powder mixing and packing machine, powder packaging machine,

cement mixing and packing machine, industrial mixing and

packing machine, dry mortar production line,etc, has become

Our company's innovation premium brand.

Our Fier Machinery factory

What we do?

★Industrial mixing and packing and crushing solutions

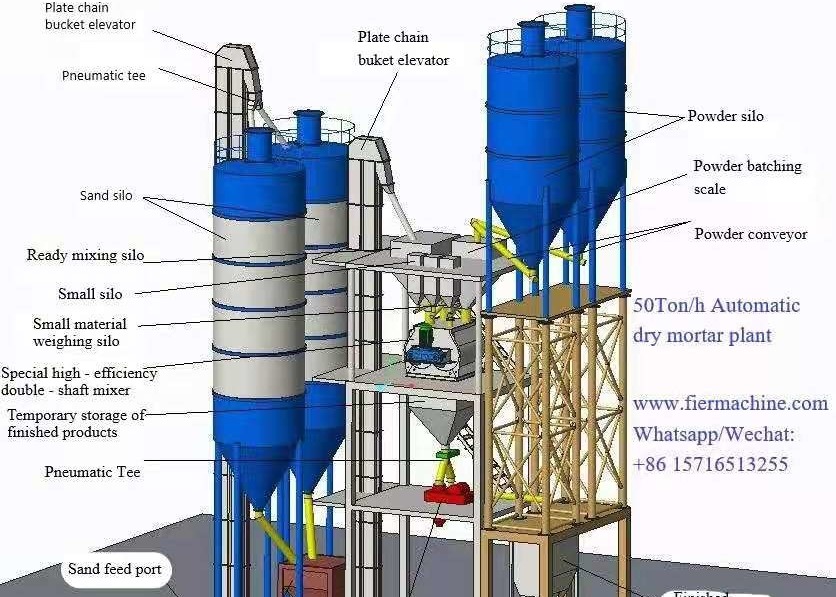

★Dry mortar processing

Within the present industrial curshing and mixing and packing business, Fier Machinery is holding a 63% market share in China and is

developing more and more dealers across Europe and North America.

While in dry mortar processing, lots of successful projects are built and earning profit for our

clients from Africa, South America, and Southeast Asia.

★ Our mission: Help you happiness developing, built your future!

★ Working style: Fast answer to your requirements in 24-hour online service.

★ Always online: FIER is striving to help you to develop a vast market and

profitable business cooperation.Two-win!

Our Team:

Our honor